Top handpiece spare parts

Top Selling Dental Products

Top Selling Dental Products

KaVo Slow Speed Tools

Rotors for KaVo

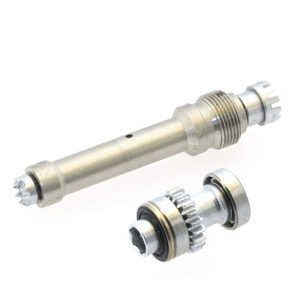

Micro Motor Rotors

Rotors for NSK

Handpiece Parts

KaVo Coupler

Handpiece Parts

NSK Slow Speed Tools

Top Selling Dental Products

Slow Speed Parts for W&H

Premium Quality Dental Parts

All our Dental Drill Parts, Contra Angle Parts, and Tools are compatible with a wide range of the world’s well-known handpiece brands Our company and our products are in no way connected with SIRONA, KaVo, BienAir, MkDent, Siemens, and NSK…. companies.

We have a wide selection of premium handpiece parts on our website that are perfectly compatible with world-famous brands of dental high-speed handpieces. Important: products are not affiliated with companies such as SIRONA, BienAir, Siemens, MkDent, NSK, and others. All our rotating parts are assembled exclusively with German Premium quality handpiece parts at affordable prices.

German Push Button Handpiece Turbines

When it comes to dental spare parts, the quality of these components is paramount for ensuring reliable and effective dental treatments. Our online store is dedicated to providing high-quality dental spare parts that are meticulously designed and manufactured using cutting-edge materials and technologies.

Whether you need High-Speed Handpieces, Low-Speed Handpieces, or Laboratory Handpieces our parts and tools are crafted to meet the highest industry standards in terms of durability, functionality, and aesthetics. Our precision-engineered spare parts seamlessly integrate with existing dental structures, ensuring optimal performance and long-lasting results. Rest assured, our dental spare parts will last as long as the original ones.

By choosing our top-notch dental spare parts, dental professionals can confidently deliver exceptional care, restoring patients’ oral health and rejuvenating their smiles. What Product Categories Can You Find on Our Website? Among the product range, you can find Dental Rotors and Turbines, parts like Push Buttons, head gears, led and xenon bulbs as well as all the necessary dental turbine repair tools for high-speed and low-speed handpieces.

What Are the Benefits of Quality Dental rotors and Push button turbines?

Dental handpiece repair parts kits like rotors/ head gears/ kits are suitable for comfortable operation at a high rotation without discomfort and vibrations for dentists and also for patients. Another important component of the dental high-speed drill turbines is that the impeller is dynamically balanced which eliminates vibration at high and low-speed rotations. Your high-speed and low-speed handpieces will operate smoothly, without vibrations, and disturbing noise for patients and also for dentists. All turbine kits are sold with necessary o-rings and washers for dental turbines and contra-angles according to the manufacturer’s user guide.

Dental Handpiece Turbines Parts

Our complete dental handpiece turbine parts are assembled exclusively with German Premium Quality Ceramic bearings which won’t wear out quickly. Whole Rotor pack Exceeds ISO Standard Chucking System. Replacement of dental parts can be done by yourself. Buy Handpiece parts for Wholesale Prices. Distributors are welcome. Worldwide Delivery!