Ersatzteile für das obere Handstück

Meistverkaufte Dentalprodukte

Meistverkaufte Dentalprodukte

KaVo Slow Speed Tools

Rotoren für KaVo

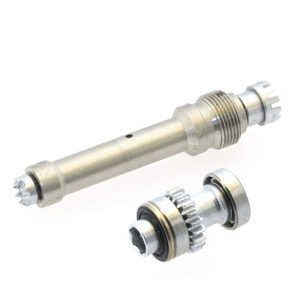

Mikromotor-Rotoren

Rotoren für NSK

Handstück Teile

Handstück Teile

NSK Slow Speed Tools

Meistverkaufte Dentalprodukte

Langsamlaufteile für W&H

Dentalteile in Premiumqualität

Alle unsere Dentalbohrerteile, Winkelstückeund Tools sind kompatibel mit einer breiten Palette von weltweit bekannten Handstückmarken Unser Unternehmen und unsere Produkte stehen in keiner Weise in Verbindung mit den Firmen SIRONA, KaVo, BienAir, MkDent, Siemens und NSK.....

Auf unserer Website finden Sie eine große Auswahl an hochwertigen Handstückteilen, die perfekt mit den weltbekannten Marken von zahnmedizinischen Hochgeschwindigkeitshandstücken kompatibel sind. Wichtig: Die Produkte stehen nicht in Verbindung mit Firmen wie SIRONA, BienAir, Siemens, MkDent, NSK und anderen. Alle unsere rotierenden Teile werden ausschließlich mit deutscher Premium-Qualität montiert Handstück Teile zu erschwinglichen Preisen.

Deutsche Druckknopf-Handstück-Turbinen

Wenn es um zahnmedizinische Ersatzteile geht, ist die Qualität dieser Komponenten für eine zuverlässige und wirksame zahnmedizinische Behandlung von größter Bedeutung. Unser Online-Shop widmet sich der Bereitstellung hochwertiger Dentalersatzteile die unter Verwendung modernster Materialien und Technologien sorgfältig entworfen und hergestellt werden.

Ganz gleich, ob Sie Hochgeschwindigkeitshandstücke, Niedriggeschwindigkeitshandstücke oder Laborhandstücke benötigen, unsere Teile und Werkzeuge werden so gefertigt, dass sie den höchsten Industriestandards in Bezug auf Haltbarkeit, Funktionalität und Ästhetik entsprechen. Unsere präzisionsgefertigten Ersatzteile fügen sich nahtlos in die vorhandenen zahnmedizinischen Strukturen ein und gewährleisten optimale Leistung und dauerhafte Ergebnisse. Sie können sicher sein, dass unsere zahnmedizinischen Ersatzteile genauso lange halten wie die Originalteile.

Durch die Wahl unserer erstklassigen zahnmedizinischen Ersatzteile können Zahnärzte und Zahntechniker mit Zuversicht außergewöhnliche Behandlungen durchführen, die Mundgesundheit der Patienten wiederherstellen und ihr Lächeln verjüngen. Welche Produktkategorien können Sie auf unserer Website finden? In der Produktpalette finden Sie Dentalrotoren und TurbinenWir bieten Ersatzteile wie Druckknöpfe, Kopfgetriebe, LED- und Xenon-Lampen sowie alle notwendigen Reparaturwerkzeuge für Hoch- und Niedergeschwindigkeits-Handstücke.

Was sind die Vorteile von Qualitäts-Dentalrotoren und Druckknopfturbinen?

Reparatur von zahnärztlichen Handstücken Teilesätze wie Rotoren/Kopfgetriebe/Kits eignen sich für einen komfortablen Betrieb bei hoher Rotation ohne Unannehmlichkeiten und Vibrationen für Zahnärzte und auch für Patienten. Ein weiterer wichtiger Bestandteil des Hochgeschwindigkeits-Dentalbohrer Turbinen besteht darin, dass das Laufrad dynamisch ausgewuchtet ist, wodurch Vibrationen bei hohen und niedrigen Drehzahlen vermieden werden. Ihre Handstücke mit hoher und niedriger Drehzahl arbeiten reibungslos, ohne Vibrationen und störende Geräusche für Patienten und auch für Zahnärzte. Alle Turbinen-Kits werden mit den erforderlichen O-Ringen und Unterlegscheiben verkauft für Dentalturbinen und Winkelstücke gemäß der Gebrauchsanweisung des Herstellers.

Zahnärztliche Handstückturbinen Teile

Unser komplettes zahnärztliche Handstück-Turbinenteile werden ausschließlich mit deutschen Premium-Qualitäts-Keramiklagern montiert, die sich nicht so schnell abnutzen. Das gesamte Rotorpaket übertrifft die ISO-Norm für das Spannsystem. Ersatz von Zahnersatzteilen kann selbst durchgeführt werden. Kaufen Teile des Handstücks für Großhandelspreise. Vertriebspartner sind willkommen. Weltweite Lieferung!