Ricambi per manipoli top

Prodotti dentali più venduti

Prodotti dentali più venduti

Strumenti KaVo a bassa velocità

Rotori per KaVo

Rotori per micromotore

Rotori per NSK

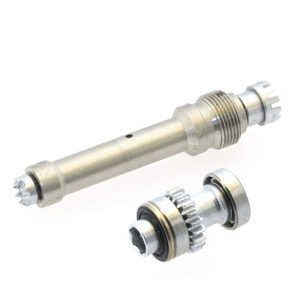

Parti del manipolo

Attacchi Rapidi per KaVo

Parti del manipolo

Strumenti a bassa velocità NSK

Prodotti dentali più venduti

Parti a bassa velocità per W&H

Parti dentali di qualità superiore

Tutti i nostri ricambi per trapani dentali, Parti del contrangolo, e gli Strumenti sono compatibile con un'ampia gamma di marchi di manipoli noti in tutto il mondo La nostra azienda e i nostri prodotti non sono in alcun modo collegati alle aziende SIRONA, KaVo, BienAir, MkDent, Siemens e NSK.....

Sul nostro sito web abbiamo un'ampia selezione di parti di manipoli di qualità superiore, perfettamente compatibili con i manipoli dentali ad alta velocità di marche famose in tutto il mondo. Importante: i prodotti non sono affiliati a società come SIRONA, BienAir, Siemens, MkDent, NSK e altre. Tutte le nostre parti rotanti sono assemblate esclusivamente con prodotti tedeschi di qualità superiore. manipolo a prezzi accessibili.

Turbine per manipoli a pulsante tedesche

Quando si tratta di ricambi dentali, la qualità di questi componenti è fondamentale per garantire trattamenti dentali affidabili ed efficaci. Il nostro negozio online è dedicato alla fornitura di ricambi dentali di alta qualità ricambi dentali che sono meticolosamente progettati e realizzati con materiali e tecnologie all'avanguardia.

Che si tratti di manipoli ad alta velocità, manipoli a bassa velocità o manipoli da laboratorio, i nostri pezzi e strumenti sono realizzati per soddisfare i più elevati standard industriali in termini di durata, funzionalità ed estetica. I nostri ricambi di precisione si integrano perfettamente con le strutture dentali esistenti, garantendo prestazioni ottimali e risultati duraturi. I nostri ricambi dentali dureranno quanto quelli originali.

Scegliendo i nostri ricambi dentali di alta qualità, i professionisti del settore possono fornire con fiducia cure eccezionali, ripristinando la salute orale dei pazienti e ringiovanendo i loro sorrisi. Quali categorie di prodotti si possono trovare sul nostro sito web? Tra la gamma di prodotti, si possono trovare rotori dentali e Turbine, parti come pulsanti, ingranaggi della testina, lampadine a led e allo xeno, nonché tutti gli strumenti necessari per la riparazione di turbine dentali per manipoli ad alta e bassa velocità.

Quali sono i vantaggi dei rotori dentali di qualità e delle turbine a pulsante?

Riparazione di manipoli dentali I kit di componenti come i rotori/ le teste/ i kit sono adatti per un funzionamento confortevole a una rotazione elevata, senza disagi e vibrazioni per i dentisti e anche per i pazienti. Un altro componente importante del trapano dentale ad alta velocità Il vantaggio delle turbine è che la girante è bilanciata dinamicamente, il che elimina le vibrazioni alle rotazioni ad alta e bassa velocità. I vostri manipoli ad alta e bassa velocità funzioneranno senza problemi, senza vibrazioni e senza rumori fastidiosi per i pazienti e per i dentisti. Tutti i kit di turbine sono venduti con gli o-ring e le rondelle necessari per turbine dentali e contrangoli secondo le istruzioni per l'uso del produttore.

Parti di turbine per manipoli dentali

Il nostro completo dentale parti della turbina del manipolo sono assemblati esclusivamente con cuscinetti ceramici tedeschi di qualità superiore che non si consumano rapidamente. L'intera confezione del rotore supera il sistema di serraggio standard ISO. Sostituzione di parti dentali può essere fatto da soli. Acquista Parti del manipolo per i prezzi all'ingrosso. I distributori sono i benvenuti. Consegna in tutto il mondo!