Turbines à bouton-poussoir pour pièces à main à grande vitesse

Push Button Turbines: Revolutionizing High Speed Handpieces in Dentistry

Contenu

In the ever-evolving field of dentistry, precision and efficiency are paramount. Dental professionals rely on a myriad of instruments and tools to provide exceptional care to their patients. Among these tools, high-speed handpieces play a crucial role in various procedures, from drilling and cutting to polishing and finishing. However, traditional high-speed handpieces have long been plagued by issues such as difficulty in bur removal, cross-contamination risks, and limitations in ergonomics. Enter the push button turbine: a game-changing innovation that promises to revolutionize the way dental professionals interact with their high-speed handpieces.

The chuck-type push-button turbines used in dental handpieces were invented by Dr. John Borden in the 1950s. Borden’s innovation revolutionized dental instrumentation, providing dentists with a more efficient and convenient tool for various procedures. The push-button design allowed for easier and quicker bur changes during dental procedures, improving overall efficiency and patient care.

This comprehensive article delves into the intricacies of push button turbines, exploring their design, functionality, and the numerous benefits they offer to both practitioners and patients. We will examine the historical context that led to their development, the engineering principles behind their operation, and the ways in which they address the shortcomings of traditional handpieces. Additionally, we will investigate the potential impact of push button turbines on patient safety, efficiency, and overall clinical outcomes.

The Evolution of High-Speed Handpieces

To truly appreciate the significance of push button turbines, it is essential to understand the historical context and challenges associated with traditional high-speed handpieces. The origins of these instruments can be traced back to the early 20th century, when the advent of air-driven turbines revolutionized the field of dentistry. These early handpieces, while groundbreaking at the time, were characterized by their bulky designs, limited maneuverability, and the need for frequent maintenance.

As technology advanced, so too did the design and functionality of high-speed handpieces. Manufacturers introduced smaller, more ergonomic models, and the incorporation of fiber-optic lighting systems improved visibility during procedures. However, despite these improvements, certain fundamental issues persisted, primarily revolving around bur retention and removal mechanisms.

Traditional handpieces typically employ a friction grip or collet system to secure the bur in place. While effective in many cases, these systems can be prone to bur slippage, particularly during high-torque procedures. Additionally, the process of removing and replacing burs can be cumbersome, time-consuming, and potentially hazardous, as it may expose dental professionals to sharp edges and aerosol contaminants.

The Push Button Turbine: A Paradigm Shift

Enter the push button turbine, a revolutionary design that seeks to address the limitations of traditional high-speed handpieces. This innovative system introduces a completely new mechanism for bur retention and removal, effectively eliminating many of the challenges faced by dental professionals.

At the core of the push button turbine lies a unique bur locking mechanism that is activated by a simple push of a button. This mechanism securely locks the bur in place, ensuring a firm grip and minimizing the risk of slippage during procedures. However, the true genius of this design lies in the ease of bur removal and replacement.

With a single push of the button, the bur is instantly released, eliminating the need for cumbersome unscrewing or prying motions. This not only streamlines the process of switching between burs but also reduces the risk of accidental injuries caused by sharp edges or aerosol contamination. Dental professionals can now quickly and safely change burs, enhancing efficiency and minimizing downtime during procedures.

Engineering Principles and Design

The push button turbine is a marvel of engineering, combining precision mechanics, advanced materials, and ergonomic design principles. To fully appreciate its capabilities, it is essential to understand the underlying engineering principles and design elements that make this innovation possible.

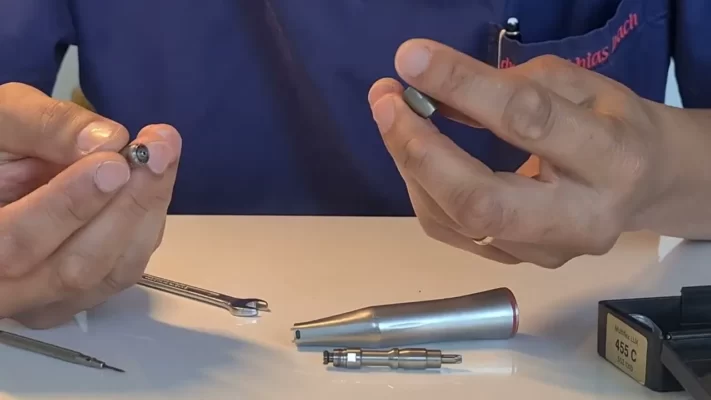

- Bur Locking Mechanism At the heart of the push button turbine lies a sophisticated bur locking mechanism. This mechanism typically consists of a series of precision-engineered components, such as locking balls, springs, and a retractable sleeve. When the push button is depressed, the mechanism engages, causing the locking balls to protrude and secure the bur in place. Conversely, when the button is released, the locking balls retract, allowing for effortless bur removal.

- Materials and Manufacturing The push button turbine is constructed from high-quality materials that are designed to withstand the rigors of dental procedures. Stainless steel, titanium, and specialized alloys are commonly used in the manufacturing of these handpieces, ensuring durability, corrosion resistance, and precise tolerances. Advanced manufacturing techniques, such as computer numerical control (CNC) machining and precision casting, enable the creation of intricate components with exceptional accuracy.

- Ergonomic Design Comfort and ease of use are essential considerations in the design of push button turbines. Manufacturers employ ergonomic principles to create handpieces that conform to the natural grip and hand movements of dental professionals. Contoured shapes, textured surfaces, and balanced weight distribution all contribute to reducing hand fatigue and improving control during procedures.

- Turbine and Motor Technology The turbine and motor systems within push button turbines are engineered for high-speed operation and efficient power transfer. Compact, high-torque motors combined with precisely balanced turbines enable these handpieces to achieve exceptional rotational speeds, often exceeding 300,000 revolutions per minute (RPM). Advanced bearings and lubrication systems ensure smooth, vibration-free operation, minimizing hand fatigue and improving precision.

- Illumination and Visibility Many push button turbines incorporate advanced illumination systems, such as LED or fiber-optic lights, to enhance visibility during procedures. These high-intensity light sources are strategically positioned to provide optimal illumination of the treatment area, reducing eye strain and improving accuracy.

Benefits of Push Button Turbines

The adoption of push button turbines in dental practices offers a multitude of benefits that extend beyond mere convenience. These advantages encompass improved patient safety, enhanced efficiency, and potential cost savings, ultimately contributing to better clinical outcomes and a more positive patient experience.

- Improved Patient Safety One of the primary benefits of push button turbines is the enhanced level of patient safety they provide. Traditional handpieces with friction grip or collet systems can potentially cause bur slippage during procedures, leading to accidental injuries or damage to oral tissues. The secure locking mechanism of push button turbines virtually eliminates this risk, ensuring that burs remain firmly in place throughout the procedure.

Furthermore, the ease of bur removal and replacement reduces the risk of exposure to sharp edges and aerosol contaminants, which can pose a threat to both dental professionals and patients. By minimizing these hazards, push button turbines contribute to a safer and more controlled clinical environment.

- Increased Efficiency and Productivity Time is a valuable commodity in any dental practice, and push button turbines offer significant efficiency gains. The quick and effortless bur changing process facilitated by the push button mechanism streamlines workflow, reducing downtime between procedures. Dental professionals can seamlessly transition from one bur to another, minimizing disruptions and maximizing productivity.

Additionally, the ergonomic design and balanced weight distribution of push button turbines can help reduce hand fatigue, allowing dental professionals to work more comfortably for extended periods. This improved comfort translates into increased focus and precision, further enhancing overall efficiency.

- Improved Ergonomics and Comfort Ergonomics play a crucial role in the dental profession, where repetitive motions and prolonged procedures can lead to musculoskeletal disorders and hand fatigue. Push button turbines are designed with ergonomic principles in mind, featuring contoured shapes and balanced weight distribution that conform to the natural grip and hand movements of dental professionals.

The elimination of cumbersome bur removal and replacement motions, such as unscrewing or prying, further reduces strain on the hands and wrists. This improved ergonomic design not only enhances comfort during procedures but also helps mitigate the risk of long-term injuries and discomfort associated with traditional handpieces.

- Cost Savings and Longevity While the initial investment in push button turbines may be higher than traditional handpieces, the long-term cost savings and extended lifespan of these instruments can make them a financially prudent choice for dental practices.

The precision engineering and high-quality materials used in push button turbines contribute to their durability and longevity. With proper maintenance and care, these handpieces can withstand the rigors of daily use for many years, reducing the need for frequent replacements and associated costs.

Furthermore, the reduced risk of bur slippage and accidental damage can translate into cost savings by minimizing the need for corrective procedures or repairs. By providing a more controlled and safer operating environment, push button turbines can potentially prevent costly complications and contribute to overall cost-effectiveness.

- Versatility and Compatibility Push button turbines are designed to be compatible with a wide range of dental procedures and equipment. Many manufacturers offer a variety of bur types and sizes that can be used with these handpieces, ensuring versatility and adaptability to different clinical situations.

Additionally, push button turbines can often be integrated with existing dental units and systems, minimizing the need for extensive equipment overhauls or compatibility issues. This versatility allows dental practices to seamlessly incorporate push button turbines into their existing workflows, maximizing the return on investment and minimizing disruptions.

Infection Control and Sterilization

In the dental field, infection control and sterilization are of paramount importance to ensure the safety of both patients and professionals. Push button turbines are designed with these critical considerations in mind, offering features and protocols that align with industry-standard infection control practices.

- Surface Materials and Design Push button turbines are typically constructed from non-porous materials, such as stainless steel or specialized alloys, which are resistant to bacterial growth and easy to clean and disinfect. The smooth, seamless surfaces minimize the risk of harboring contaminants, while the inclusion of autoclave-safe components facilitates thorough sterilization procedures.

- Bur Changing Protocol The push button mechanism for bur removal and replacement minimizes the risk of exposure to sharp edges and aerosol contaminants, reducing the potential for cross-contamination. Dental professionals can follow established protocols for safe bur handling and disposal, further enhancing infection control measures.

- Sterilization and Maintenance Push button turbines are designed to withstand the rigors of sterilization processes, such as autoclaving or chemical disinfection. Manufacturers provide detailed instructions and guidelines for proper cleaning, disinfection, and sterilization procedures, ensuring that these handpieces remain safe and compliant with industry standards.

Additionally, regular maintenance and servicing of push button turbines are recommended to ensure optimal performance and longevity. Certified technicians can inspect, lubricate, and replace worn components, minimizing the risk of potential contamination or failure during procedures.

Integration and Implementation

Incorporating push button turbines into a dental practice requires careful consideration and planning. While the benefits of these handpieces are well-established, the successful implementation and integration into existing workflows and systems is crucial for maximizing their potential.

- Training and Familiarization Proper training and familiarization are essential for dental professionals to fully embrace and utilize the capabilities of push button turbines. Manufacturers often provide comprehensive training materials, instructional videos, and hands-on workshops to ensure that practitioners are proficient in the operation, maintenance, and sterilization of these handpieces.

Additionally, ongoing training and refresher courses can help dental teams stay up-to-date with the latest advancements and best practices related to push button turbine technology.

- Equipment Integration and Compatibility When introducing push button turbines into a dental practice, it is important to evaluate their compatibility with existing equipment and systems. Many manufacturers offer handpieces that can seamlessly integrate with various dental units, ensuring a smooth transition and minimizing the need for extensive equipment overhauls.

Furthermore, dental practices may need to consider the necessary infrastructure and utilities required to support push button turbines, such as air and water supply lines, electrical connections, and suction systems.

- Workflow Optimization Implementing push button turbines provides an opportunity to optimize and streamline existing workflows within the dental practice. By analyzing and mapping out current procedures, dental teams can identify areas where push button turbines can introduce efficiencies and enhance productivity.

This may involve revising protocols for bur handling, sterilization, and equipment setup, as well as exploring new techniques or procedures that leverage the capabilities of push button turbines. Continuous evaluation and adjustments to workflows can help maximize the benefits of these handpieces and improve overall practice efficiency.

- Cost and Budgeting Considerations While the long-term benefits of push button turbines can outweigh the initial investment, dental practices must carefully consider the associated costs and budgeting requirements. This may include the purchase of handpieces, additional equipment or accessories, staff training expenses, and potential downtime during the implementation phase.

Developing a comprehensive budget and exploring financing options can help dental practices effectively manage the costs associated with adopting push button turbine technology. Additionally, factoring in potential cost savings from improved efficiency, reduced maintenance, and decreased risk of complications can provide a more accurate assessment of the return on investment.

Future Advancements and Innovations

The dental industry is constantly evolving, driven by technological advancements and a relentless pursuit of better patient care. As push button turbines continue to gain traction and widespread adoption, manufacturers and researchers are exploring new innovations and enhancements to further improve their performance and capabilities.

- Intelligent Handpiece Systems The integration of smart technology and connectivity into push button turbines is an area of active research and development. Intelligent handpiece systems could potentially incorporate sensors and data-tracking capabilities, allowing dental professionals to monitor and analyze various parameters such as rotational speed, torque, and bur wear.

This data could be leveraged to provide real-time feedback, optimize performance, and even predict maintenance or replacement needs, ultimately enhancing efficiency and reducing downtime.

- Advanced Materials and Coatings Advancements in materials science and manufacturing techniques may lead to the development of push button turbines with improved durability, corrosion resistance, and wear characteristics. Specialized coatings or surface treatments could enhance the lifespan and performance of these handpieces, while also contributing to better infection control and sterilization capabilities.

- Ergonomic Enhancements Ergonomics will remain a key focus area for push button turbine development. Manufacturers may explore new designs, contours, and weight distribution strategies to further enhance comfort and reduce hand fatigue during extended procedures. Additionally, the incorporation of haptic feedback or vibration dampening technologies could provide dental professionals with a more intuitive and responsive experience.

- Improved Illumination and Visibility Advancements in lighting technologies, such as more efficient and brighter LED systems or specialized optics, could further improve visibility and illumination during procedures. Enhanced visibility not only contributes to better clinical outcomes but also reduces eye strain and fatigue for dental professionals.

- Enhanced Compatibility and Integration As dental practices continue to adopt digital technologies and advanced equipment, the seamless integration and compatibility of push button turbines with these systems will become increasingly important. Manufacturers may focus on developing handpieces that can seamlessly interface with various dental software, imaging systems, and treatment planning platforms, enabling a more streamlined and interconnected workflow.

Conclusion

Push button turbines represent a revolutionary advancement in the world of high-speed handpieces, offering dental professionals a solution that addresses longstanding challenges and limitations. By introducing a simple yet ingenious mechanism for bur retention and removal, these handpieces enhance patient safety, improve efficiency, and promote better ergonomics and comfort for practitioners.

The benefits of push button turbines extend far beyond mere convenience, encompassing improved clinical outcomes, cost savings, and a more positive patient experience. As the dental industry continues to embrace technological advancements, the adoption of push button turbines is poised to become a standard practice, setting a new benchmark for precision, efficiency, and quality of care.

However, the journey of innovation does not end here. Manufacturers, researchers, and dental professionals will continue to explore new frontiers, pushing the boundaries of what is possible with push button turbine technology. From intelligent handpiece systems and advanced materials to ergonomic enhancements and improved integration, the future holds exciting possibilities for further refinements and advancements.

As dental practices navigate the ever-changing landscape of healthcare, the push button turbine stands as a testament to the power of innovation and the relentless pursuit of better solutions. By embracing this technology, dental professionals can confidently step into a future where precision, efficiency, and patient safety are seamlessly intertwined, setting the stage for a new era of excellence in dental care.

- Kavo Push Button Turbines

- Turbines à bouton-poussoir NSK

- Turbines à bouton-poussoir Sirona

- W&H Push Button Turbines

- Turbines à bouton-poussoir Bien Air

- BA International Push Button Turbines

- Mk-Dent Push Button Turbines

- Castellini Push Button Turbines

- Anthos Push Button Turbines

- Lares Push Button Turbines

- Midwest Push Button Turbines

- Faro Push Button Turbines

- Fona Push Button Turbines

- Osada Push Button Turbines

- Brasseler Push Button Turbines

- Turbines à bouton-poussoir Codent

- Siemens Push Button Turbines

- Turbines à bouton-poussoir Coxo

- Planmeca Push Button Turbines

- Stern Weber Push Button Turbines

FAQ about Chuck Type Push Button Turbines on Dental Handpieces

Chuck type push button turbines are components of dental handpieces used by dentists for various procedures. They feature a push-button mechanism for quick and easy changing of burs and tools.

Dr. John Borden is credited with inventing the chuck type push button turbines in the 1950s, revolutionizing dental instrumentation.

Chuck type push button turbines offer several advantages, including quick and easy bur changes, improved efficiency during dental procedures, and enhanced patient comfort due to reduced procedure times.

Chuck type push button turbines work by utilizing a push-button mechanism that releases and secures dental burs or tools. Dentists can quickly swap out burs during procedures, reducing downtime and improving workflow.

While chuck type push button turbines have become widespread in modern dental equipment, compatibility may vary depending on the specific make and model of the dental handpiece. It’s essential to ensure compatibility before purchasing or using these turbines.

Yes, chuck type push button turbines can be repaired and maintained by skilled dental equipment technicians. Routine maintenance, such as cleaning and lubrication, can help prolong the lifespan and performance of these turbines.

There can be replaced ball bearings in case the chuck has enough grip force which can be evaluated only by experienced dental handpiece technicians.

While chuck type push button turbines offer numerous benefits, they may have higher initial costs compared to traditional turbines. Additionally, improper use or maintenance can lead to decreased performance or malfunction

Chuck type push button turbines are available from various dental equipment suppliers and manufacturers. Dentists can inquire with their preferred suppliers or search online for reputable vendors.

One of the most reliable supplier of dental turbines for high speed handpieces is Dental Rotors company from Italy which supply worldwide spare parts and tools fro handpiece repair.