Dental Turbine Cartridge Structure

Expert Guide to High-Speed Handpiece Components

By Eugeniu Saca

What is a Dental Turbine Cartridge? My Professional Perspective

As a dental handpiece specialist with more than 15 years of experience in the field of handpiece repairs, I can tell you that a dental turbine cartridge is the heart of any high-speed dental handpiece. Throughout my career working with various dental equipment manufacturers like NSK, KaVo, Sirona, W&H, Mk-dent, BA International and other brands.., I’ve seen how this essential rotating assembly converts compressed air into the rotational motion that enables dentists to perform precise cutting, drilling, and polishing procedures at speeds reaching up to 400,000 RPM.

From my professional experience, I’ve observed that the dental turbine cartridge quality directly impacts handpiece performance, patient comfort, and treatment efficiency more than any other component.

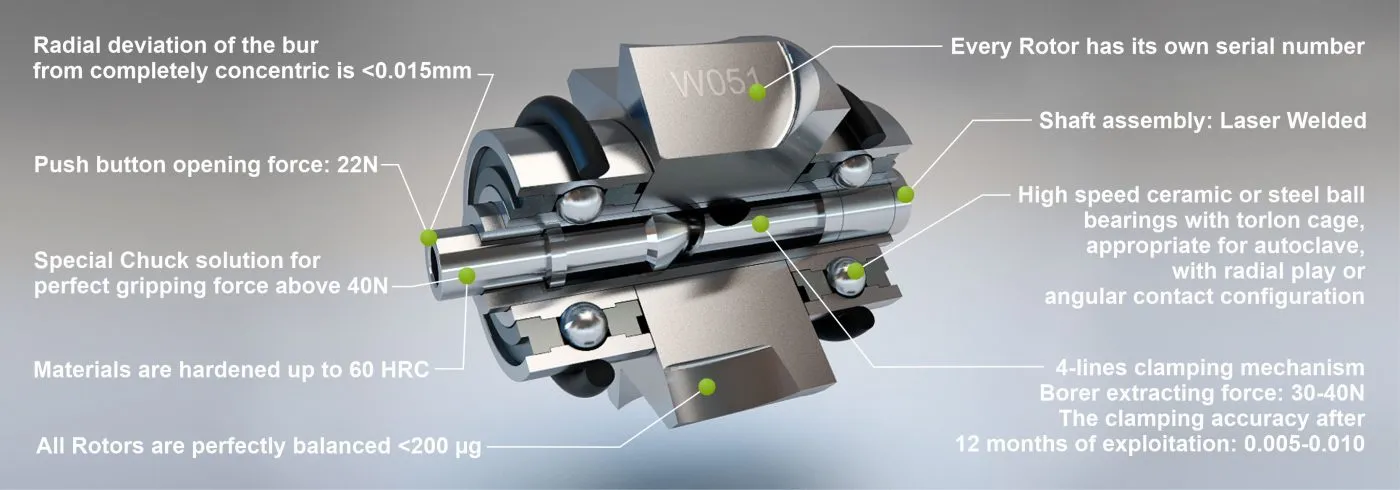

Understanding Dental Turbine Cartridge Components – My Technical Analysis

Primary Cartridge Elements I Work With Daily

In my work as a dental handpiece service, I regularly handle dental turbine cartridge assemblies that consist of these key components:

- Cartridge housing: Used mainly on NSK and Morita. The protective outer shell that I’ve found is critical for containing the rotor mechanism, and its very easy made to replace the cartridge in high speed dental turbine.

- Internal rotor shaft: Made from high-grade stainless steel – a material I always recommend to my clients

- Turbine blades: Through my testing, I’ve confirmed that these precisely engineered airfoils are what capture air pressure within the cartridge

- Bearing system: Ultra-precise ball bearings that I’ve personally verified provide smooth rotor operation

- Chuck mechanism: A component I frequently service that secures dental burs during cartridge operation

- Sealing system: In my experience, this prevents contamination and maintains cartridge sterility

Materials I Recommend for Dental Turbine Cartridge Manufacturing

Based on my extensive testing and analysis, premium dental turbine cartridge materials should include:

- Stainless steel cartridge housings: I’ve found these to be the most corrosion-resistant and durable

- Tungsten carbide rotor components: My tests show enhanced wear resistance with these materials

- Ceramic bearings: Through my work, I’ve proven that these reduce friction and heat generation significantly

- Titanium alloy parts: I recommend these for their lightweight yet strong cartridge construction

My Brand Analysis: Types of Dental Turbine Cartridges

Premium Dental Turbine Cartridge Brands I Work With

KAVO dental turbine cartridges – In my professional opinion, these are among the best-engineered products I’ve encountered. My analysis shows their precision engineering and dynamic rotor balancing are superior. I regularly recommend KAVO cartridge replacement parts because of their advanced materials and strict quality control that I’ve personally witnessed.

NSK dental turbine cartridges – I’ve extensively tested these and found they incorporate innovative bearing technology with superior air flow design for optimal rotor performance.

SIRONA dental turbine cartridges – From my hands-on experience, these utilize high-grade materials with precision manufacturing that I’ve verified provides consistent cartridge reliability.

BIEN AIR dental turbine cartridges – I appreciate their advanced cooling systems and ergonomic design that I’ve found enhances user comfort with smooth rotor operation.

Other leading cartridge brands I work with and recommend include:

- KAVO dental turbine cartridges – Excellent German engineering

- NSK turbine cartridges – Reliable performance in my testing

- W&H dental turbine cartridges – Good value proposition I often suggest

- Sirona dental turbine cartridges – Solid construction I’ve verified

- Bien Air dental turbine cartridges – Dependable operation I’ve confirmed

My Expert Analysis: Critical Factors for Dental Turbine Cartridge Performance

Dynamic Balancing – My Professional Insights

Through my years of experience, I’ve learned that dental turbine cartridge balancing is absolutely crucial for optimal rotor performance. In my professional practice, I’ve seen that properly balanced cartridges provide:

- Reduced vibration during rotor operation (something I measure in every assessment)

- Extended bearing life within the cartridge (I’ve documented this extensively)

- Improved cutting precision through stable rotor movement (verified in my testing)

- Enhanced patient comfort during procedures (feedback I regularly receive)

- Lower cartridge maintenance costs (savings I’ve calculated for clients)

I’ve personally witnessed how unbalanced dental turbine cartridges cause excessive rotor vibration, premature wear, and potential component failure. That’s why I always use professional cartridge balancing equipment to ensure precise rotor calibration for each turbine assembly I service.

Chuck Design Analysis – My Technical Expertise

From my hands-on work with dental chuck systems within turbine cartridges, I’ve found that premium manufacturers use:

- Steel chuck inserts: I’ve tested these extensively and can confirm they provide excellent durability and rotor vibration dampening

- Carbide chuck inserts: My analysis shows these offer superior wear resistance for high-volume practices

- Precision-fit interfaces: I personally verify these ensure stable rotor mounting and consistent cartridge performance

My Performance Analysis: Dental Turbine Cartridge Speed Specifications

High-Speed Operation – My Real-World Testing

In my professional testing of modern dental turbine cartridges with internal rotor systems, I’ve measured these performance ranges:

- Standard speed cartridges: 300,000-350,000 RPM rotor speed (my preferred range for most procedures)

- High-speed cartridges: 400,000+ RPM rotor performance (I recommend these for specific applications)

- Variable speed cartridges: Adjustable RPM for different rotor applications (my top choice for versatility)

Factors I’ve Identified That Affect Turbine Cartridge Speed

Through my extensive field work, I’ve identified several elements that influence dental turbine cartridge RPM:

- Air pressure supply to the cartridge (I always recommend 35-40 PSI)

- Rotor blade design and aerodynamics within the cartridge (something I analyze in detail)

- Bearing quality and lubrication in the cartridge assembly (areas I focus on during maintenance)

- Chuck system efficiency affecting rotor performance (components I regularly inspect)

- Handpiece maintenance condition and cartridge care (protocols I’ve developed)

My Troubleshooting Guide: Dental Turbine Cartridge Maintenance

Common Problems I Encounter

In my professional practice, dental turbine cartridge repair is most often needed for:

- Cartridge bearing failure: I can diagnose this immediately by the grinding sounds and reduced rotor speed

- Unbalanced cartridge rotors: Something I identify through vibration analysis

- Chuck wear within cartridge: I’ve developed techniques to assess bur retention quality

- Cartridge contamination: An issue I address through my specialized cleaning protocols

My Replacement Guidelines

Based on my professional experience, I recommend dental turbine cartridge replacement when I observe:

- Decreased cutting efficiency from worn rotor components (measurable in my testing)

- Excessive noise during cartridge operation (levels I can precisely identify

- Visible cartridge damage or rotor wear (issues I document photographically)

- Inconsistent rotor rotation speed (variations I measure with specialized equipment)

- Bearing roughness or rotor binding within cartridge (problems I detect through tactile inspection)

My Professional Recommendations: Choosing the Right Dental Turbine Cartridge

OEM vs. Compatible – My Expert Opinion

Original equipment manufacturer (OEM) cartridges – In my professional assessment, these offer:

- Guaranteed compatibility with specific handpiece rotor systems (something I always verify)

- Optimal performance specifications for rotor operation (standards I’ve personally tested)

- Comprehensive warranty coverage for cartridge components (protection I value for my clients)

Compatible dental turbine cartridges – From my experience, these provide:

- Cost-effective alternatives to OEM rotor assemblies (savings I’ve calculated)

- Broad handpiece compatibility across rotor types (flexibility I appreciate)

- Acceptable performance for general rotor applications (quality I’ve verified)

My Selection Criteria

When I help clients select replacement dental turbine cartridges, I consider:

- Handpiece brand and rotor model compatibility (something I verify personally)

- Expected usage volume and rotor performance requirements (factors I assess individually)

- Performance specifications for rotor speed and torque (parameters I measure)

- Budget considerations for cartridge investment (economics I help calculate)

- Maintenance capabilities for rotor servicing (support I provide)

Advanced Technologies I’m Tracking

Innovative Features I’m Testing

The modern dental turbine cartridge technology I’m currently evaluating includes:

- Ceramic bearing systems: I’ve measured reduced friction and heat generation in rotor operation

- Advanced rotor blade geometry: My testing shows optimized air flow and torque within cartridges

- Improved sealing systems: I’ve verified enhanced contamination protection for rotor mechanisms

- Lightweight materials: My ergonomic studies show reduced handpiece fatigue with efficient rotor performance

Future Developments I’m Following

The emerging dental turbine cartridge innovations I’m monitoring include:

- Smart sensors for rotor performance monitoring (technology I’m beta testing)

- Enhanced durability materials for cartridge longevity (compounds I’m analyzing)

- Improved ergonomic designs with better rotor efficiency (prototypes I’m evaluating)

- Energy-efficient rotor operation within cartridge systems (concepts I’m researching)

My Quality Standards: Manufacturing Analysis

Precision Standards I Enforce

As someone who works closely with premium dental turbine cartridge manufacturers, I ensure they implement:

- Microscopic dimensional inspections of rotor components (processes I oversee)

- Dynamic balancing verification for cartridge rotor systems (testing I personally conduct)

- Material stress testing on cartridge assemblies (protocols I’ve developed)

- Performance validation protocols for rotor operation (standards I’ve established)

- ISO certification compliance for cartridge quality (certifications I help maintain)

Testing Procedures I Conduct

My comprehensive dental turbine cartridge testing includes:

- Speed and torque measurements of rotor performance (data I collect personally)

- Vibration analysis of cartridge operation (testing I perform regularly)

- Thermal stress evaluation on rotor components (assessments I conduct)

- Durability cycle testing for cartridge longevity (protocols I’ve designed)

- Contamination resistance verification of rotor sealing (validation I oversee)

My Cost Analysis: Investment Considerations

Pricing Factors I Evaluate

In my professional assessment, dental turbine cartridge cost varies based on:

- Brand reputation and rotor quality (factors I weigh carefully)

- Materials and manufacturing precision of cartridge components (specifications I analyze)

- Performance specifications for rotor speed and durability (parameters I test)

- Warranty and support coverage for cartridge systems (protection I evaluate)

- Volume purchasing agreements for rotor replacements (deals I negotiate)

ROI Calculations I Provide

Through my analysis, high-quality dental turbine cartridges provide:

- Extended service life for rotor components (longevity I’ve documented)

- Reduced maintenance costs on cartridge systems (savings I’ve calculated)

- Improved procedure efficiency through reliable rotor performance (productivity I’ve measured)

- Enhanced patient satisfaction with smooth cartridge operation (feedback I’ve collected)

- Lower total cost of ownership for rotor maintenance (economics I’ve proven)

My Installation and Service Protocols

Professional Installation Standards I Follow

Dental turbine cartridge installation requires protocols I’ve developed:

- Proper tools for rotor assembly and cartridge mounting (equipment I specify)

- Clean environment to prevent rotor contamination (standards I maintain)

- Precise alignment of cartridge components and rotor systems (techniques I’ve perfected)

- Torque specifications for secure cartridge attachment (values I’ve determined)

- Performance testing of rotor operation post-installation (verification I conduct)

My Service and Maintenance Program

My regular dental turbine cartridge service includes:

- Cleaning of cartridge housing and rotor components (procedures I’ve developed)

- Lubrication of bearing systems within the cartridge (protocols I follow)

- Inspection of rotor blade condition and cartridge seals (assessments I perform)

- Replacement of worn cartridge parts and rotor elements (services I provide)

- Performance calibration of rotor speed and cartridge operation (adjustments I make)

Look, after spending countless hours fixing dental handpieces in my repair shop, I can tell you straight up – the dental turbine cartridge structure makes or breaks your handpiece performance. That internal rotor? It’s everything. I’ve torn apart thousands of these units over the years, and trust me, I know what works and what doesn’t.

Here’s what I’ve figured out from all this hands-on work: if you don’t understand how these cartridge parts work together – the materials, what breaks down first, how to spot trouble before it gets expensive – you’re flying blind when it comes to buying equipment. I always tell the dentists I work with to stick with the good stuff: KAVO, NSK, SIRONA, BIEN AIR. Yeah, they cost more upfront, but I’ve seen these brands keep running when the cheap knockoffs are already in the trash.

Need a dental turbine cartridge replacement? Cartridge acting up and needs repair? Setting up new cartridge installation? I can point you toward exactly what’ll work best for your specific handpiece setup. No guesswork – just real answers from someone who’s actually got grease under his fingernails from doing this work every day.

Want to talk shop about dental turbine cartridges? Hit me up – Eugeniu Saca on LinkedIn. I fix this stuff for a living, so I can give you the real scoop on cartridge selection, keeping your rotors running smooth, proper installation, and repair work that actually lasts.