Dental turbines stand as a crucial instrument in the arsenal of modern dental practices. In this article, we will delve into the intricate details of the components that constitute the of High-performance KaVo turbine rotors, a device that seamlessly blends advanced technology and precision to enhance the efficiency and practicality of dental procedures.

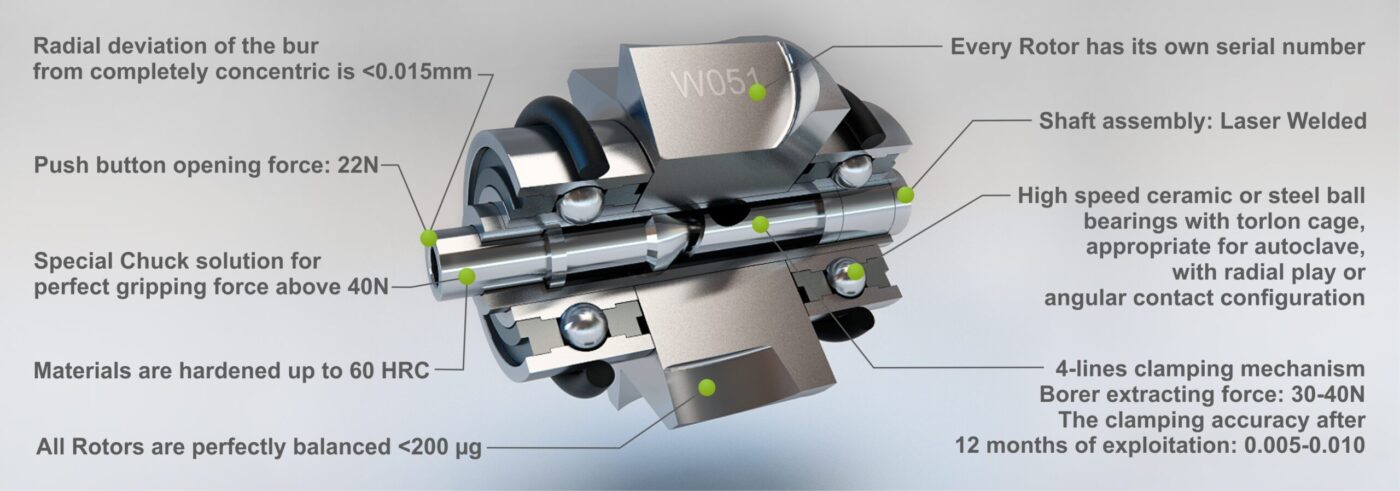

The replacement rotor turbine is a key component of the high-speed dental turbine, responsible for driving the rotation of the bur at speeds of up to 450 000 rotations per minute. This part is replaceable and plays a crucial role in maintaining the turbine’s functionality over time. The precision-engineered rotor plays a vital role in the overall performance of the turbine. If you are searching original code part number Kavo GENTLEforce® 6000 / 6000B here is the manufacturer’s original part number code 1.001.3888 Its seamless rotation ensures the smooth execution of dental procedures. It is essential to have quality replacement rotors assembled with German ceramic bearings, offering a long lifespan, comfort, and precision. Rotors assembled with German Ceramic Bearings from MYONIC provide comfort as they are silent, benefiting both the dentist and the patients. Purchase premium-quality rotors for Kavo turbines from our online shop, with a warranty of up to 12 months. They are assembled with MYONIC (original Kavo bearings). Push Button in Dental High-Speed Turbines In the realm of dental instrumentation, the push button stands out as a crucial component in high-speed turbines, significantly enhancing the efficiency and ease of various dental procedures. Let’s delve into the multifaceted functions of the push button, especially its pivotal role in simplifying the insertion and extraction of burs—a feature that brings both comfort and speed to the interchangeability of different bur types during dental workflows. Effortless Bur Insertion and Extraction: At the core of the push button’s functionality is its role in streamlining the process of bur insertion and extraction. By simply engaging the push button, dentists can swiftly load and unload burs with minimal effort. This seamless interchangeability is invaluable in dynamic dental environments, where different procedures necessitate a rapid change of burs. Speedy Interchangeability for Diverse Treatments: The push button’s role in facilitating the quick interchangeability of burs allows dental professionals to adapt rapidly to the unique requirements of different treatments. Whether switching between cutting, polishing, or other dental procedures, the push button enables a seamless transition, ultimately saving valuable time and enhancing overall workflow efficiency. Buy a compatible press button for Kavo on our store with no compromises of the quality. O-rings, acting as seals, ensure the airtight integrity of the turbine. Strategically positioned, they prevent air leaks, safeguarding the turbine’s performance by maintaining a consistent airflow and steady rotation of the bur, minimizing movement and contributing to the precise workflow of the dentist with the dental instrument. O-rings in a dental turbine, as spare parts, serve important functions related to sealing and maintaining the integrity of the turbine assembly. Here are the key functions of O-rings in a dental turbine: It’s important to note that O-rings are typically made of durable and flexible materials, such as rubber or silicone, which allows them to create effective seals while accommodating movement and changes in pressure within the turbine system. When considering O-rings as spare parts, it’s advisable to use those recommended or provided by the turbine’s manufacturer to ensure compatibility and optimal performance. In the context of a dental turbine, washers typically refer to small, flat, and often round components that serve various functions within the turbine assembly. These washers are commonly used as part of the bearing system, providing support and facilitating smooth movement of rotating parts. Here are some functions of washers in a dental turbine: It’s important to note that the specific design and placement of washers can vary between different models and manufacturers of dental turbines. When considering spare parts for dental turbines, including washers, it’s advisable to refer to the manufacturer’s guidelines and specifications to ensure compatibility and proper functioning within the turbine system. Fiber optic rods are a characteristic feature of many modern dental turbines. Transmitting light from the source to the bur’s tip, they ensure optimal visibility during procedures. Fiber optic rods represent a technological advancement, illuminating the working area precisely and allowing dentists to perform procedures with enhanced clarity. Due to advanced technologies in LED and their brightness, and their decreasing size, the implementation of LED technology in the head of dental turbines is becoming widespread, excluding the old style of fiber optic rods as a technology in modern high-speed handpieces. The lighting technology is a key element of the dental turbine. LED bulbs and xenon bulbs provide bright and clear illumination, improving visibility and enabling dentists to execute procedures with precision. The choice between LED and xenon bulbs allows for customization based on the dentist’s preferences, providing consistent and reliable lighting for diverse dental procedures. Keeping a stock of spare parts for Kavo GENTLEforce® 6000/6000B is a proactive measure to minimize downtime, allowing dental professionals to swiftly address any unexpected issues maintain uninterrupted workflow, and minimize the cost of servicing your dental high-speed turbine. The service/repair key is necessary to open the back cap of the dental turbine. It is mainly used for repair purposes and is essential for the replacement of the turbine rotor. Buying this wrench offers you the possibility to replace the replacement rotor for the Kavo 6000B dental turbine by yourself. Normally, replacing the turbine rotor is not difficult and takes up to 7 minutes, from extracting the rotor with O-rings and washers, lubricating and cleaning the head, to inserting back the O-rings, washers, and turbine rotor, making your turbine work perfectly as a completely new high-speed turbine. O-rings, acting as seals, ensure the airtight integrity of the turbine. Strategically positioned, they prevent air leaks, safeguarding the turbine’s performance by maintaining a consistent airflow and steady rotation of the bur, minimizing movement and contributing to the precise workflow of the dentist with the dental instrument. O-rings in a dental turbine, as spare parts, serve important functions related to sealing and maintaining the integrity of the turbine assembly. Here are the key functions of O-rings in a dental turbine: It’s important to note that O-rings are typically made of durable and flexible materials, such as rubber or silicone, which allows them to create effective seals while accommodating movement and changes in pressure within the turbine system. When considering O-rings as spare parts, it’s advisable to use those recommended or provided by the turbine’s manufacturer to ensure compatibility and optimal performance. Original Part number code of original KaVo 6000B O-rings code 0.200.6172 In the context of a dental turbine, washers typically refer to small, flat, and often round components that serve various functions within the turbine assembly. These washers are commonly used as part of the bearing system, providing support and facilitating smooth movement of rotating parts. Here are some functions of washers in a dental turbine: It’s important to note that the specific design and placement of washers can vary between different models and manufacturers of dental turbines. When considering spare parts for dental turbines, including washers, it’s advisable to refer to the manufacturer’s guidelines and specifications to ensure compatibility and proper functioning within the turbine system. Fiber optic rods are a characteristic feature of many modern dental turbines. Transmitting light from the source to the bur’s tip, they ensure optimal visibility during procedures. Fiber optic rods represent a technological advancement, illuminating the working area precisely and allowing dentists to perform procedures with enhanced clarity. Due to advanced technologies in LED and their brightness, and their decreasing size, the implementation of LED technology in the head of dental turbines is becoming widespread, excluding the old style of fiber optic rods as a technology in modern high-speed handpieces. The lighting technology is a key element of the dental turbine. LED bulbs and xenon bulbs provide bright and clear illumination, improving visibility and enabling dentists to execute procedures with precision. The choice between LED and xenon bulbs allows for customization based on the dentist’s preferences, providing consistent and reliable lighting for diverse dental procedures. Keeping a stock of spare parts for Kavo GENTLEforce® 6000/6000B is a proactive measure to minimize downtime, allowing dental professionals to swiftly address any unexpected issues maintain uninterrupted workflow, and minimize the cost of servicing your dental high-speed turbine. The service/repair key is necessary to open the back cap of the dental turbine. It is mainly used for repair purposes and is essential for the replacement of the turbine rotor. Buying this wrench offers you the possibility to replace the replacement rotor for the Kavo 6000B dental turbine by yourself. Normally, replacing the turbine rotor is not difficult and takes up to 7 minutes, from extracting the rotor with O-rings and washers, lubricating and cleaning the head, to inserting back the O-rings, washers, and turbine rotor, making your turbine work perfectly as a completely new high-speed turbine. Turbine Replacement Parts are precision-engineered components designed to replace worn-out or malfunctioning turbines in Kavo handpieces, restoring optimal performance. Consider replacing your Kavo turbine if you notice a decline in performance, unusual sounds, or signs of wear. Regular maintenance can also help identify the need for replacement. Yes, Kavo Replacement Parts are designed for specific Kavo handpiece models, ensuring seamless compatibility and optimal performance. Parts must be selected according to the manufacturer’s Original Part Number or according to the model of the handpiece. A lot of dental turbines from Kavo can be replaced in-house in a dental studio and you only need just Cap Wrench. On our blog, you can find all replacement turbine processes. But if you notice some dents or the head of the dental handpiece then it’s recommended to have turbine replacement performed by a dental professional or follow the guidelines provided in the product manual for proper installation. Regularly lubricate your Kavo turbine as per the manufacturer’s recommendations or during routine maintenance, ensuring smooth operation and prolonged lifespan. But we advise as experts in dental handpiece parts to lubricate after 1-3 hours of work. This will keep your life turbine much longer than usual. Turbine Replacement Parts offer improved rotational speed, torque, and overall performance, contributing to enhanced precision during dental procedures. The lifespan of a dental turbine replacement depends on usage, maintenance, and the specific model. Regularly monitor performance and consider replacement if efficiency diminishes. It’s advisable to lubricate after 1-3 hours of work and clean the chuck with a brush once a day to eliminate teeth powder and saliva, which can damage the chuck and reduce its lifespan. Yes, Kavo offers replacement turbines with various speed options, catering to different dental procedures and preferences. Kavo Replacement Parts are commonly available through authorized dealers and distributors, but direct sales to end-user customers are not offered. Check their official channels for availability. However, there is an opportunity to purchase compatible parts at half the price, often with similar quality and properties. Follow the cleaning guidelines provided in the product manual. Typically, use a non-corrosive disinfectant and ensure thorough drying before reassembly. Please read our blog post about turbine maintenance. No, Kavo High-Speed Parts are not compatible with Low-Speed Parts because they involve different types of components with completely different working principles. Dental turbines are driven by air pressure, and only the turbine rotor rotates the bur. In Slow-Speed Handpieces, the bur is mechanically driven by a headgear linked to an intermediate shaft and other components interconnected mechanically. The source of power/rotation is variable and can be adjusted by an Electric or Air Micromotor. Usually, Slow-Speed Handpieces have higher torque and are mechanically driven, providing more control over the rotation during dental procedures. Original KAVO turbine rotors are assembled with Angular Ceramic Ball Bearings from MYONIC Manufacturing. These are the best high-speed mini bearings on the market, capable of resisting high load pressure and speeds up to 450 000 rotations per minute. If you receive your turbine back from repair with a higher level of noise, it may indicate that the bearings are of low quality or are assembled with steel bearings instead of ceramic. Ceramic bearings offer a lower level of noise and a longer lifespan, but they require more careful maintenance, including the use of premium-quality lubricants and lubrication after 1-3 hours of work. Yes, adhere to the maintenance guidelines outlined in the product manual, including regular lubrication, cleaning, and inspection to ensure optimal performance. Follow the specific instructions for your Kavo turbine replacement model and handpiece type to ensure correct installation and compatibility. You can refer to our user guide on how to perform a Do-It-Yourself handpiece turbine replacement in your dental studio. Yes, Kavo Turbines are versatile and can be used for a range of dental procedures, including both anterior and posterior restorative work. Ensure proper installation and lubrication. If the noise persists, consult the product manual or contact Kavo’s customer support for assistance. Please turn back the handpiece to the repair service to check the issue why the handpiece turbine is noisy Yes, Kavo provides technical support through their customer service channels if the handpiece is repaired in their repair shops. Reach out for guidance on proper installation, troubleshooting, or any related queries. You can receive technical support from our experts through our store or via our blog. Contact us via online chat or by filling out the contact form.

Kavo Turbine Replacement Parts

Replacement Turbine Rotors

Press Buttons (Back Caps)

O-Rings

Washers

Steel Wavy Washers for Kavo Turbines:

Fiber Optic Rod for Turbines

LED and Xenon Bulbs

Service / Repair Key:

O-Rings

Wavy Washers

Original Parts Number of Washers used in Kavo GENTLEforce® 6000B are:

Fiber Optic Rod

LED and Xenon Bulbs

Service / Repair Key:

FAQs - about KaVo Replacement Parts

89,96 € excl. VAT

(4)

98,16 € excl. VAT

98,16 € excl. VAT

98,16 € excl. VAT

(2)

106,35 € excl. VAT

(2)

98,16 € excl. VAT

(4)

98,16 € excl. VAT

98,16 € excl. VAT

(1)

98,16 € excl. VAT

110,66 € excl. VAT

(1)

135,25 € excl. VAT

New

(1)

135,25 € excl. VAT

98,16 € excl. VAT

98,16 € excl. VAT

98,16 € excl. VAT

98,16 € excl. VAT

106,35 € excl. VAT

(4)

98,16 € excl. VAT

98,16 € excl. VAT

98,16 € excl. VAT

39,92 € excl. VAT

39,92 € excl. VAT

39,92 € excl. VAT

39,92 € excl. VAT

39,92 € excl. VAT

What are Turbine Replacement Parts?

How do I know if I need to replace my Kavo turbine?

Are Kavo Replacement Parts compatible with all Kavo handpieces?

Can I replace the turbine in my Kavo handpiece myself?

How often should I lubricate my Kavo turbine?

What benefits do Turbine Replacement Parts offer?

Are Turbine Replacement Parts Covered by a Warranty?

Manufacturers recommend using genuine Turbine Replacement Parts to ensure optimal compatibility, performance, and adherence to quality standards. However, based on our experience of more than 10 years, all parts supplied by us, which are assembled with Original KAVO bearings (manufactured by MYONIC), have proven their efficiency. There is almost no difference between original Kavo parts and compatible parts from DENTAL ROTORS company.

How long does a dental turbine replacement typically last?

Are there different speed options for Kavo Turbines?

Can I purchase Kavo Replacement Parts directly from the manufacturer?

How do I clean my Kavo Turbine?

Are Handpiece Parts Compatible with both High-speed and low-speed handpieces?

Can a Turbine Rotor improve the noise level of my handpiece?

Is there a specific maintenance routine for Kavo Turbine Replacement Parts?

Are there any special considerations when replacing a Kavo turbine in an air-driven handpiece?

Can a Kavo Turbine be used for both anterior and posterior restorative work?

What should I do if my Kavo handpiece becomes noisy after turbine replacement?

Can I get technical support for installing Kavo Turbine Replacement Parts?