Dental Micromotor Parts

Micromotors are small electric motors that are used in a variety of applications, ranging from medical devices to robotics. These micromotors are designed to be small, efficient, and reliable, and they can provide precise movement and control in a compact package. Like any other mechanical device, however, micro motors require regular maintenance and repair to ensure that they continue to operate at their best. This is where micromotor spare parts come in.

Dental Micromotor spare parts are components that are designed to replace worn or damaged parts in a micro motor. These parts can include everything from bearings and gears to brushes and coils. By replacing these parts, users can extend the lifespan of their micromotors and ensure that they continue to function as intended.

Bearings

One of the most common micro motor spare parts is the bearing. Bearings are small, round components that support the rotating shaft of a motor. They are designed to reduce friction and wear, and they help to ensure that the motor operates smoothly and efficiently. Over time, however, bearings can become worn or damaged, leading to increased friction and a decrease in motor performance. By replacing these worn bearings with new ones, users can restore their motor to its original condition and ensure that it continues to perform as intended.

Gears

Another common micro motor spare part is the gear. Gears are toothed components that transmit power and motion from one part of a motor to another. They can be made from a variety of materials, including metal, plastic, and even ceramics. Like bearings, gears can become worn or damaged over time, which can lead to decreased performance and reliability. By replacing these worn gears with new ones, users can restore their motor power and ensure that it continues to function smoothly.

Carbon Brushes

Brushes are another important micromotor spare part. Carbon brushes are small, rectangular components that conduct electrical current from the power source to the motor’s coils. Over time, however, brushes can become worn or damaged, which can lead to poor electrical contact and decreased motor performance. By replacing these worn carbon brushes with new ones, users can restore their motor’s electrical conductivity and ensure that it continues to operate at its best.

Coils are another important micromotor spare part. Coils are the wire-wound components that generate the magnetic fields that drive the motor’s rotation. Over time, however, coils can become damaged or burned out, which can lead to decreased motor performance and reliability. By replacing these damaged coils with new ones, users can restore their motor’s magnetic fields and ensure that it continues to operate as intended.

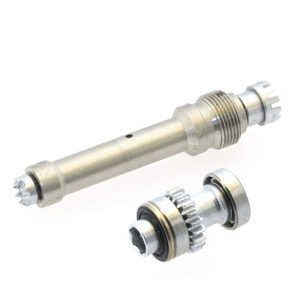

Complete Rotors assembled with Bearings for Dental Micro Motors

Other micromotor spare parts include shafts, housings, and even entire motor assemblies. Shaft and housing components can become worn or damaged over time, which can lead to decreased performance and reliability. By replacing these worn or damaged components, users can restore their motor to its original condition and ensure that it continues to perform as intended. In some cases, it may be necessary to replace an entire motor assembly, especially if the motor has suffered catastrophic damage or has simply reached the end of its useful life.

When choosing micromotor spare parts, it is important to choose parts that are compatible with the specific motor being used. Many micromotors are designed to be highly specialized, and different motors may require different types of spare parts. Additionally, it is important to choose high-quality parts that are designed to meet or exceed the original manufacturer’s specifications. By using high-quality parts, users can ensure that their micro motors continue to operate at their best, even under the most demanding conditions.

Overall, micromotor spare parts play a critical role in ensuring the ongoing operation and reliability of micro motors. By replacing worn or damaged components with high-quality replacement parts, users can extend the lifespan of their motors and ensure that they continue to function as intended. With proper maintenance and care, a micro motor can provide years of reliable performance, making it an essential component in

Chuck?

A chuck for a micromotor is a component that is used to hold various types of rotary tools or attachments in place. It is an important accessory for micro motors used in applications such as dental drills, jewelry making, and other precision machining tasks.

The chuck is typically attached to the end of the motor’s output shaft and is designed to securely hold a wide range of tools such as drill bits, grinding wheels, and sanding discs. Chucks are available in various sizes and designs to accommodate different types of tools.

The most common type of chuck for micro motors is a collet chuck. A collet chuck uses a collet, which is a small cylindrical sleeve that compresses around the shank of a tool to hold it securely in place. Collets are available in a variety of sizes to accommodate different tool shank diameters.

Other types of chucks that are used with micro motors include keyless chucks and pin chucks. A keyless chuck uses a mechanism that allows the user to tighten and loosen the chuck without the need for a special tool, such as a chuck key. A pin chuck is a simple, spring-loaded chuck that is designed to hold very small tools, such as drill bits or needles.

When selecting a chuck for a micromotor, it is important to consider the size and type of tools that will be used. It is also important to choose a chuck that is compatible with the motor’s output shaft. Chucks are available in various shaft sizes and styles, so it is important to choose one that will fit the motor’s output shaft.

In summary, a chuck for a micromotor is a component that is used to hold various types of rotary tools or attachments in place. It is an important accessory for micromotors used in precision machining tasks and is available in a variety of sizes and designs to accommodate different types of tools. When selecting a chuck, it is important to consider the size and type of tools that will be used and to choose a chuck that is compatible with the motor’s output shaft. Buy Premium Dental Micromotor Parts from dental-rotors.com

FAQs

1. What are the essential components of a micromotor?

Micromotors typically consist of a rotor, stator, bearings, and a power source. The rotor is the rotating part, the stator is the stationary part, and bearings facilitate smooth rotation.

2. Which brands are known for high-quality micromotor parts?

Prominent brands include NSK, Saeyang, and Marathon, known for their precision engineering and durable micromotor components.

3. What role do bearings play in micromotor functionality?

Bearings in micromotors reduce friction, ensuring smooth rotation of the rotor. Brands like SKF and NSK produce bearings designed for optimal performance in micromotors.

4. Can I replace the brushes in my micromotor?

Yes, many micromotors have replaceable brushes. Brands like Kavo and Bien-Air offer brush replacement kits, enhancing the longevity of your micromotor.

5. Are there specific lubricants recommended for micromotor maintenance?

Yes, specialized lubricants like those from W&H and Nouvag are recommended for micromotor maintenance. Proper lubrication ensures optimal performance and longevity.

6. What is the significance of a collet in micromotors?

A collet securely holds the bur or tool in place. Brands like Suhner and NSK provide high-quality collets designed for precision and stability during operation.

7. How do I choose the right power source for my micromotor?

Consider the power requirements specified by the micromotor’s brand, such as Bien-Air or Saeyang. Ensure compatibility with power sources like control units and foot pedals.

8. Can I use accessories from different brands with my micromotor?

It is advisable to use accessories recommended by the micromotor’s brand to ensure compatibility and optimal performance. Mixing brands may affect functionality.

9. What are the common maintenance practices for micromotors?

Regular cleaning, lubrication, and checking for wear are essential maintenance practices. Brands like Kavo and Marathon provide detailed maintenance guidelines.

10. Are there specific safety precautions for micromotor usage?

Follow safety guidelines provided by brands like NSK and Sirona. Ensure proper ventilation, use safety glasses, and adhere to recommended operating conditions.

11. What is the purpose of a micromotor handpiece?

The handpiece is a crucial component that holds the bur or tool. Brands like Saeshin and W&H offer ergonomic handpieces for precise control during procedures.

12. How do I troubleshoot common micromotor issues?

Refer to troubleshooting guides provided by brands like Sirona and Bien-Air. Common issues include overheating, abnormal noise, or inconsistent speed.

13. Can I upgrade the power and speed of my micromotor?

Some brands, such as Nouvag and NSK, offer upgraded control units with variable speed settings, allowing users to customize the performance of their micromotors.

14. Are there environmentally friendly micromotor components available?

Certain brands, such as Sirona and Nouvag, are committed to eco-friendly practices. Look for components made from recyclable materials or those with reduced environmental impact.

15. How do I choose the right bur for my micromotor?

Consider the application and material you are working with. Brands like Kavo and Saeyang offer a variety of burs suitable for different procedures.

16. What is the lifespan of micromotor components?

The lifespan varies by brand and usage. Following recommended maintenance practices can extend the lifespan of components. NSK and W&H provide information on component durability.

17. Can I use my micromotor for both dental and jewelry applications?

Some micromotors, like those from Saeyang and Marathon, are versatile and can be used across various applications. Check the brand’s specifications for compatibility.

18. How do I properly store my micromotor when not in use?

Refer to guidelines from brands like Sirona and NSK for proper storage recommendations. This typically involves keeping the micromotor in a clean, dry environment.

19. Are there wireless micromotor options available?

Yes, brands like Bien-Air and Saeshin offer wireless micromotors for increased flexibility and convenience during procedures.

20. Can I purchase micromotor parts individually for replacement?

Yes, many brands, including Marathon and Kavo, offer individual replacement parts such as rotors, stators, and brushes for convenient and cost-effective maintenance.