replacement dental turbines

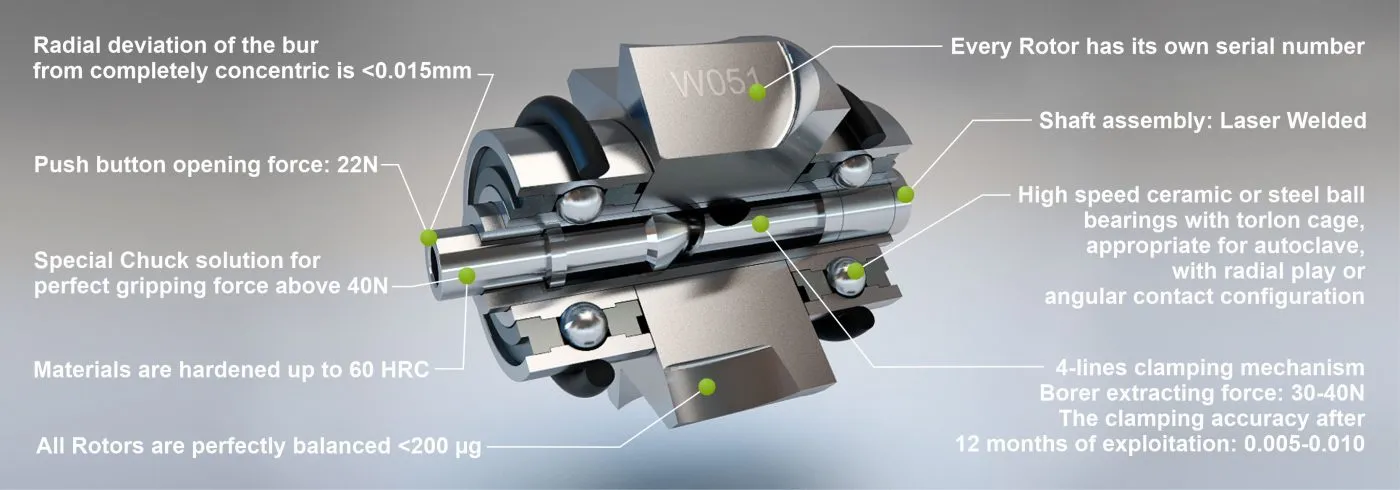

Every High-Speed Handpiece is driven by a combination of spare parts like chuck assembled with impeller and ball bearings.

This combination of parts is named dental turbine.

Every Dental High-Speed Handpiece manufacture uses different types by size and designs replacement dental turbines according to dentist needs.

Quality Replacement Dental Turbines

Usually, there are two types of heads in dental High-Speed Turbines:

- Standard head

- Small head

Accordingly to this type of heads of handpieces inside also there are bigger and small dental turbines or dental cartridges which have different sizes of bearings, impellers, and chucks.

To achieve smooth run and exactness of working with dental Highspeed handpiece its necessary there is necessary to have a high precision assembly of parts.

To achieve high-quality dental turbines there must use only the finest materials and have extremely strict requirements in terms of design and production. This is possible only using high precision CNC machines for the production of chucks and impellers and dynamically balanced turbines will give smooth run on highest speeds without any vibrations.

All replacement dental turbines are assembled with high precision ceramic micro ball bearings manufactured by World known in industry German Factories like MYONIC or GRW.

Replacement Dental Cartridges

Replacement Dental Cartridge is the same Dental Turbine but only is covered by a Protective Shield/Cartridge which protects the Dental Turbine/Rotor assembly protect to from dirt, saliva, dust from teeth and this type of replacement dental cartridges was innovatively introduced on market by NSK Dental which was a revolutionary entrance with success on dental market and loved by dentists.

NSK dental Turbines has fame of high precision and reliability.

One more advantage of this revolutionary innovation was the ease of replacement of dental cartridges because dentists could replace them by themselves and made a lot of savings of time and money by making themselves replacement in 5 minutes.

Original dental Turbine vs Non Original

We agree that original parts in 70% of cases are better than non original dental parts but below we are advantages and disadvantages

Original dental Turbines

- High Cost of Dental turbine/cartridge

- Design of chucks created and produced by the manufacture

- Ball bearings ordered by third party manufacture like MYONIC, NSK, Barden

Non-Original Dental Turbines (supplied by www.dental-rotors.com)

- 50-70% lower price

- Same Ceramics Angular of Radial Ball Bearings from MYONIC

- High precision chucks with warranty 6-12 months

- The same design of impellers dynamically balanced 100% as original dental turbines/cartridges

Our replacement dental turbines and replacement dental cartridges operate at the same high level as the original and are made with high quality and durable ceramic bearings making them ideal for high torque and RPM applications. We offer lubricated and non-lubricated dental turbines from top brands like KaVo, NSK, Sirona, W&H, Bien Air, Mk-Dent, Morita, Faro, Fona, Castellini and other famous brands Dental to suit your particular preference and use case.

Check here the Dental Handpiece Tools for dental cartridge and dental turbine replacement.

Dental turbines are the handpieces that dentists use to power tools such as high-speed drills and burs for work like cutting teeth and removing decay. Over time, these turbines can wear out or break and need to be replaced. As technology improves, newer turbine models provide better performance, durability, and features. This article will provide an overview of considerations around replacing dental turbines.

When to Replace Dental Turbines

Some signs that indicate a dental turbine may need replacement include:

- Noticeable loss of power or performance

- Overheating during use

- Unusual noises or vibrations

- Rusted areas or other visible damage

- Frequent clogs that are difficult to clear

Many experts recommend proactively replacing turbines every 3-5 years as preventative maintenance to maximize performance and lifecycle. Additionally, sterilization procedures can accelerate wear and tear.

Comparing Turbine Models and Features

Newer turbine models provide technological and ergonomic improvements. Key variables to compare include:

- Number of air vents – More vents improve airflow and cooling

- Noise output – Better sound insulation reduces noise

- LED lighting – Integrated lighting improves visibility

- Sterilization – Autoclavable or sterilizable models allow better disinfection

- Weight – Lighter models increase user comfort during long procedures

- Warranties and lifecycle – Better warranties provide more coverage

Top brands known for quality and innovation include KaVo, NSK, and W&H. It helps to test different models firsthand to evaluate factors like vibration, grip, and visibility.

Purchasing Replacement Dental Turbines

Replacement dental turbines involve considerable upfront investment. Prices range widely from around $300 up to over $1,000 per unit. Key purchasing considerations include:

- Intended usage and length of procedures

- Quantity for outfitting full office versus just backups

- Compatibility with existing tubing, couplings, fiber optics

- Available budgets and financing options

To maximize value, purchasing programs from dental distributors allow combining volume discounts across product categories. Bundled warranty services can provide additional peace of mind by covering repairs and maintenance.

Maintaining and Caring for Dental Turbines

To maximize performance and longevity of replacement dental turbines, proper maintenance is critical. Following best practices around cleaning, sterilization, and usage helps safeguard your investment.

Recommended Cleaning Methods

Effective cleaning is the first step to prepare turbines for sterilization. Buildup of dental materials, blood, and biofilms can impede performance. Recommended methods include:

- Flushing with water immediately after use

- Using enzyme detergents tailored for ultrasonic cleaners

- Avoiding harsh chemicals that can damage equipment

Thorough cleaning that avoids residue buildup is crucial for allowing proper sterilization.

Effective Sterilization Guidelines

Sterilization destroys bacteria and pathogens to provide disinfected dental equipment. For dental turbines, recommended methods include:

- Steam autoclaving – The leading method, with care taken not to exceed max temperatures

- Dry heat sterilization – Requires longer time at lower temperatures

- Chemical vapor systems – Offer lower temperature alternatives

Be sure to follow manufacturer guidelines on allowable temperatures, exposure times, recommended chemical agents, and allowed sterilization cycles.

Protecting Against Drops and Impacts

Dental turbines contain precision bearings and components vulnerable to damage from drops and impacts during usage or reprocessing. Ways to help prevent damage include:

- Using secure handpiece holders near work areas

- Storing in protective casings when not in use

- Avoiding harsh contact with hard surfaces

- Care when transporting between areas

With extra care taken during handling and transport, dental turbines can better maintain alignment and calibration.

Troubleshooting Common Dental Turbine Issues

Despite regular maintenance, dental turbines can still experience periodic performance problems or malfunctions. Reviewing the most common issues can help identify appropriate troubleshooting steps.

Loss of Power and Speed

Gradual power loss usually indicates buildup of debris, scoured air bearings, or worn parts. Potential fixes include:

- Cleaning air and water lines to remove accumulated sludge

- Flushing with lubricants to displace built-up deposits

- Replacing worn bearings or rotor components

Sudden loss of power may signal damaged supply lines or failure of a turbine component.

Overheating Problems

Excess heat during turbine usage can signal impaired cooling or friction buildup. Troubleshooting steps cover:

- Checking sufficient airflow from dual water and air line connections

- Flushing to remove accumulated mineral deposits

- Replacing worn bearings allowing metal-to-metal friction

Rust deposits inside air or water channels can indicate corrosion issues over time.

Unusual Noise and Vibrations

New rattling, buzzing or shaking sensations signal possible internal damage. Potential causes and fixes include:

- Imbalanced rotor due to damaged blades – Replace rotor

- Worn ball bearings – Replace bearings

- Bent turbine head – Attempt realignment or replace

Damaged rotors can require turbine replacement if vibrations persist after servicing.

Improving Dental Turbine Lifespan and Performance

Beyond maintenance and troubleshooting issues as they occur, some best practices can help improve longevity and performance of replacement dental turbines.

Lubricating After Sterilization

Lubricating turbines after each sterilization cycle helps reduce friction and protects against corrosion. Special turbine oils help replenish protective barriers.

Periodic Repairs and Refurbishment

Many manufacturers offer economical repair services to refurbish turbines. This allows servicing worn parts like rotor shafts and replacing bearings/blades.

Tracking Usage and Trends

Recording usage hours for individual turbines can guide optimal replacement Cycles. Reviewing historical reliability also identifies bad models.

Maintaining Spares/Backups

Keeping backup turbines enables immediate replacements if repair delays ever impact critical office workflows. They also allow technicians to service individual units without office disruptions.

New Dental Turbine Technologies

As technology progresses, new and emerging dental turbine innovations promise even better performance and longevity.

Magnetic Bearing Designs

Magnetic bearings hover the shaft using electromagnetic suspension for near frictionless rotation. They increase speeds, power, reliability, and lifespan.

Enhanced Head Designs

Lighter metals, finer machining tolerances, and vibration dampening allow high precision cutting at up to 500,000 RPM speeds.

Software Analytics and Sensors

“Smart turbine” models record sensor data on operating conditions to predict failures and customize care recommendations for optimal uptime.

Inventory Monitoring/Ordering

Sensors can automatically detect low lubricant/detergent levels to trigger reorder alerts, ensuring reprocessing supplies stay in stock.

Mobile App Integration

Mobile apps allow remote monitoring to check usage trends, upcoming service needs, and real-time operating conditions from anywhere.